SUCO – Your specialist for pressure monitoring and transmission technology

SUCO Robert Scheuffele GmbH & Co. KG, well-known by its trade name SUCO, is well established as a specialist for products in the field of fluid technology and power transmission. Pressure monitoring of hydraulic or pneumatic systems is secured by an extensive product range. Mechanical pressure and vacuum switches, tailor-made versions with plug or cable, explosion proof pressure switches according to the new ATEX directive have gained an excellent reputation all over the world.

SUCO manufactures robust mechanical pressure switches which can be adjusted in a pressure range from 0.1 to 400 bar and reach an overpressure safety up to 600 bar. Several thousands of variants of these diaphragm or piston pressure switches are being operated in different applications for almost all gaseous and liquid media.

SUCO hydrogen pressure switches and pressure transmitter

Hydrogen is one of the most important alternative energy sources of the future and will continue to grow in importance. A versatile energy source that can be used for the generation of electricity, heat and fuels.

SUCO pressure switches and pressure transmitters reliably and safely monitor the pressure e.g. in hydrogen electrolysis, in compressors, in high pressure storage tanks and gas cylinders, in pipelines, in vehicle technology, on fuel cells or hydrogen engines, in valve technology and in the equipment of H2 filling stations and H2 tanker vehicles, … and many more.

Pressure switches and pressure transmitters of the SUCO group of companies with the brands SUCO and ESI have been used for many years for pressure monitoring of hydrogen and oxygen. We have used the experience gained and the requirements of our customers to develop new pressure transmitters and mechanical pressure switches especially for hydrogen. High pressure ranges up to 5000 bar, explosion protection according to ATEX, hydrogen compatible sensors made of titanium and housings made of 316L are some innovations that have been incorporated in these series.

Mechanical pressure switches

SUCO has been manufacturing mechanical pressure switches for liquids and gaseous media for many decades. Also the use with hydrogen has a long tradition with us. Mechanical pressure switches are always used when reliable and robust, but cost-effective monitoring of pressures is required, whether to monitor the minimum pressure in lines or gas cylinders, or to close safety valves or shut down compressors if maximum pressures are exceeded. Our modular pressure switch system allows an enormous variety of variants. Especially when used in series products, this allows us to adapt our pressure switches to your requirements.

Optionally available ATEX / IECEX certifications, IP6K9K, a high overpressure safety and an extremely robust design, which can also be used under strong vibrations or unfavorable environmental conditions, enable a long service life and safe monitoring of your limit pressures.

Pressure transducer and sensors

The ESI hydrogen pressure transmitters are turned from a special titanium alloy for the measuring cell and the wetted parts from a titanium block. Thus the sensor is manufactured without seals, high pressure cells from 1000 bar we even manufacture without welding seams, which helps to avoid any weak points especially for the use with hydrogen. This material has successfully passed the hydrogen compatibility test according to ISO1114-2:2017 in accordance with the European regulations EC 79/2009 and EU 406/2010.

The combination of titanium sensing elements with SoS sensors has a long tradition at ESI, this material choice allows the construction of a long term stable sensor that has a high accuracy. Our measurement ranges up to 5000 bar make this transmitter the preferred choice for use on hydrogen storage tanks and pipelines. But we also offer the same technology for low pressures and also in vacuum measurement applications. We are convinced that ESI pressure transmitters are the right choice for use with hydrogen.

With optional Atex approvals, marine approvals and a wide range of different analog and digital signals – up to USB connection – ESI offers a broad portfolio that is unique in the field of hydrogen pressure measurement technology.

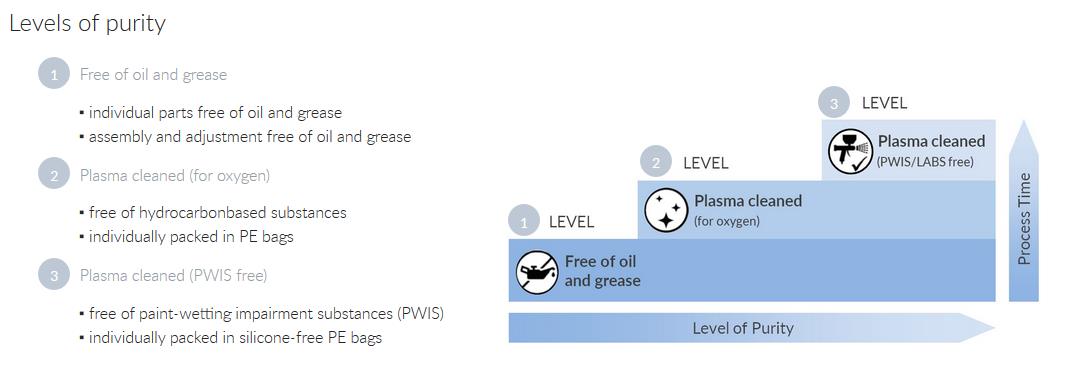

Plasma cleaning for oxygen and PWIS / LABS free applications

We offer our customers plasma-cleaned pressure switches and transmitters for various industrial and medical applications. The plasma cleaning process is subject of our internal quality management process according to DIN ISO 9001:2015. The high level of purity (max. 20 mg/m² organic residues) is regularly verified by a national accreditation body (DAkkS).

When handling oxygen, the country-specific safety and accident prevention regulations must be observed. For oxygen applications, we recommend using exclusively plasma-cleaned pressure switches and transmitters with EPDM sealing.

The requirements for components free of paint impairment substances (PWIS/LABS) have also increased in recent years. By extending the plasma cleaning process and using silicone-free gloves and PE bags, we are able to offer PWIS/LABS compliant pressure switches and transmitters for the OEMs and paint shops.

More information here.